Corded vs. Cordless Tools: Which Are Better

In any DIY project, tools play a starring role. And one of the biggest questions I find myself coming back to is this: corded vs. cordless tools—which are better? It’s not a one-size-fits-all answer, and depending on the task, my preference can shift. There are times I swear by the convenience of a battery-powered driver, and other times when nothing beats the nonstop performance of a corded saw. Over time, I’ve developed a set of real-world insights that help me choose which is best for each job.

This article dives deep into both tool types and looks at how they perform across the areas that matter: power, portability, cost, durability, and workflow. My goal is to help anyone facing the corded vs. cordless tools debate make a decision based on what really happens in the workshop, not just specs or branding.

Whether you’re building furniture, remodeling a room, or taking on light repairs, your choice in tools makes a difference. Here’s everything I’ve learned about choosing between these two categories, based on countless hours of cutting, sanding, drilling, and fixing things around the house.

Power and Performance

One of the most significant differences I notice between corded and cordless tools is how they deliver power. With a corded tool, I get constant, uninterrupted current from the wall. That means no fluctuations, no dips in performance, and no worries about running out of juice mid-task. For jobs like continuous drilling in masonry or long rip cuts with a circular saw, that consistency makes a big difference.

Cordless tools, on the other hand, have come a long way. The new generation of lithium-ion batteries delivers impressive power, sometimes matching or even surpassing their corded cousins in bursts. I’ve used cordless impact drivers that deliver more torque than corded ones, and today’s brushless motors help extend battery life and performance even further.

Still, when comparing corded vs. cordless tools purely by runtime and power, corded usually wins for high-demand applications. But cordless models are catching up fast and, in many cases, are more than powerful enough for DIY work.

Convenience and Portability

For portability and ease of movement, cordless tools are the clear winner. Not being tethered to an outlet changes the entire flow of a job. I can take a cordless drill to the backyard, a cordless jigsaw up a ladder, or a cordless sander to the far end of my garage without dragging cords around. It also means no searching for extension cords, no tripping hazards, and fewer interruptions.

Corded tools restrict movement unless I’m close to a power source, and I’ve lost count of how many times I’ve had to stop mid-job to untangle a cord or replug a tool when I move. That kind of disruption can slow things down, especially in a small or obstacle-filled space.

In the corded vs. cordless tools discussion, I give the edge to cordless for mobility and overall convenience—especially for quick tasks or jobs in remote or awkward locations.

Cost Considerations

When building out a tool collection, budget always comes into play. Corded tools generally cost less than their cordless equivalents. If I compare a corded circular saw with a cordless one, the price difference can be significant—especially once I factor in the battery and charger that many cordless tools require separately.

Over time, replacing or upgrading batteries adds to the total cost of ownership. I’ve had batteries die after a couple of years, even with moderate use, and replacements don’t come cheap. That’s a hidden cost people often overlook when investing in cordless tools.

On the flip side, cordless tools can save time and money in other ways. For example, not needing to run extension cords across a property or pay for cord management tools can offset the initial investment. If I had to pick a winner in this category, I’d say corded tools have the edge for affordability—but only if you plan to use them in fixed workspaces.

Battery Life and Downtime

One thing I’ve learned with cordless tools is to always have spare batteries on hand. There’s nothing worse than running out of power halfway through a job. On long or intensive tasks, batteries can drain fast, especially if you’re cutting hardwood or using a tool with a high load.

Corded tools eliminate this concern. As long as there’s power, they keep going. No need to charge, swap, or manage battery levels. That makes a huge difference when I’m working on large builds or using tools continuously over several hours.

Still, modern battery technology has improved. Fast chargers and extended battery packs are reducing downtime. I often rotate two batteries—using one while the other charges—which keeps me going without too much interruption. But when you’re looking at corded vs. cordless tools, battery life is a real consideration, especially if you’re doing demanding or time-sensitive work.

Tool Lifespan and Durability

In my experience, corded tools tend to last longer. They’re simpler machines with fewer electronic parts, and they’re less prone to failure from heat or overcharging. My corded router, for example, has seen years of heavy use and still runs like the day I bought it. Cordless tools, by contrast, often face more wear due to complex internal electronics and battery dependencies.

That said, I’ve had some very rugged cordless tools that withstood drops, weather, and tough materials. Durability depends just as much on the brand and build quality as the power source.

If you’re investing for the long haul and don’t want to worry about batteries degrading, corded tools usually offer more reliable longevity. But cordless models have improved so much that with proper care, they’re more than durable enough for most home and hobby projects.

Workflow and Productivity

How tools fit into a workflow really shapes which ones I reach for. For quick repairs, small builds, or punch list items, I nearly always grab a cordless tool. They save me time and hassle when I just need to make a few cuts or tighten a few screws. They’re ready to go without setup.

For more complex or extended jobs—say, building cabinets, cutting 2x4s, or sanding large surfaces—I often go corded. The continuous power, stronger performance, and lower maintenance help me stay productive over long sessions.

When it comes to corded vs. cordless tools and workflow, it’s a toss-up. Cordless wins on agility and setup time; corded wins on sustained performance and fewer interruptions.

Safety Considerations

Cordless tools offer a cleaner and safer workspace. Without cords snaking across the floor, I’ve had fewer trips and fewer damaged tools from accidental yanks. In tight spaces or when working on ladders, cordless tools feel a lot safer.

Corded tools, however, have the advantage of consistent power, which sometimes means smoother performance and fewer surprises. A cordless tool might stall or shut off unexpectedly when the battery dies, which can be dangerous if you’re midway through a cut.

Both types have built-in safety features, but cordless tools edge out in overall user safety due to the reduced clutter and better handling freedom.

Storage and Space

If your shop or storage space is limited, cordless tools are easier to manage. Without cords and with more compact footprints, I can fit more cordless tools into a toolbox or wall mount. Many even come with stackable cases that make storage neat and easy.

Corded tools, especially those with large motors or attachments, can be bulky and harder to store neatly. Their cords also require separate management, which means more hooks, ties, or drawers.

For small workshops or mobile toolboxes, cordless tools are the better choice in terms of efficient storage.

Tool Categories Where Cordless Dominates

There are some areas where cordless tools just make more sense. Here are a few tools I always prefer cordless:

- Drills and Impact Drivers – Lightweight, versatile, and rarely used for long continuous periods, cordless models win hands down.

- Oscillating Multi-Tools – Great for detail work in tight spaces where cords would get in the way.

- Flashlights and Jobsite Lights – A no-brainer for portability and ease of setup.

- Nail Guns – Modern cordless nailers are fast, clean, and far less finicky than their pneumatic ancestors.

Tool Categories Where Corded Shines

And then there are tools that I still prefer corded for:

- Circular Saws – For long cuts in thick material, I need consistent, uninterrupted power.

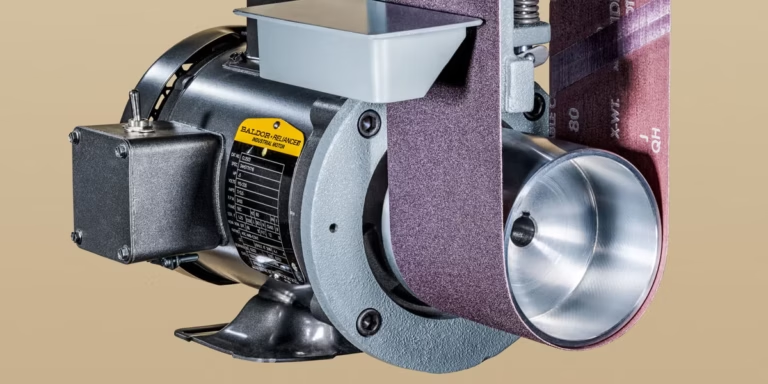

- Routers – High RPMs and heavy loads make a corded router more reliable.

- Angle Grinders – Corded models typically offer more torque and handle better under stress.

- Jigsaws – While cordless versions exist, corded ones still feel smoother and better balanced to me.

Hybrid Models and the Middle Ground

Some tools blur the line. I’ve seen models that offer both corded and cordless functionality, especially with battery inverters or dual-power inputs. These are usually more expensive, but they provide great flexibility. If you work in different environments and don’t want to double up your tool collection, this could be a great solution.

My Personal Verdict

After using both extensively, I don’t pick a side in the corded vs. cordless tools debate. Instead, I’ve built a hybrid shop. I rely on cordless tools for speed, convenience, and everyday tasks. My corded tools come out when I need raw, sustained power or when I’m doing work that demands precision and long runtime.

If I had to start over and could only choose one type, I’d go cordless for most light- to medium-duty projects, especially if portability matters. But I’d eventually add back corded versions of my high-demand tools to round out the setup.

Final Thoughts

In the end, corded vs. cordless tools isn’t about which is universally better—it’s about what fits your needs best. Both types have their strengths, and smart DIYers learn to leverage them based on the job at hand. Whether you’re framing a wall or fixing a cabinet hinge, picking the right tool type can make your project smoother, safer, and more efficient.

I’ve learned to appreciate the strengths of each. Corded tools are dependable workhorses that never quit. Cordless tools are nimble partners that follow me anywhere. And when used right, both deserve a place in every serious DIYer’s collection.