Why You Should Own a Torque Wrench

A torque wrench might not seem like the flashiest addition to a DIY toolkit, but the more projects I take on, the more I’ve come to appreciate its precision and necessity. Whether I’m tightening bolts on a lawn mower, assembling furniture, or doing brake work on my vehicle, having the exact level of torque applied to a fastener makes a huge difference—not just in performance but also in safety. There’s a reason professional mechanics, contractors, and engineers all have one in their toolkits.

If you’ve ever stripped a bolt, cracked a component, or had something shake loose after assembly, you’ll understand why proper torque matters. In this article, I’m going to share my experience and thoughts on why you should own a torque wrench, how it works, where it becomes essential, and what to look for when buying one.

What Is a Torque Wrench?

Before I started using one regularly, I thought torque wrenches were specialized tools reserved for auto mechanics and professional tradespeople. In reality, they’re incredibly useful for everyday DIYers like myself. A torque wrench is a precision tool designed to apply a specific amount of force (or torque) to a fastener, usually a nut or bolt.

Unlike a regular socket wrench or spanner, which can easily lead to overtightening or undertightening, a torque wrench helps ensure that bolts are secured just right—not too loose, not too tight. This is especially important in mechanical systems where torque specifications are crucial to functionality and safety.

I learned quickly that using the proper torque can mean the difference between a successful repair and a potential failure. That alone makes a strong case for why you should own a torque wrench.

Preventing Damage and Ensuring Safety

One of the biggest reasons I added a torque wrench to my toolbox was to prevent damaging parts when tightening fasteners. Overtightening a bolt might not seem like a big deal, but it can lead to stripped threads, snapped bolts, or even cracked casings. I’ve seen it happen, and it’s frustrating—not to mention costly.

Using a torque wrench allows me to follow manufacturer guidelines, particularly for sensitive parts like engine components, brake systems, and even certain appliances or electronics. It’s not just about avoiding damage; it’s also about safety. Bolts that are too tight or too loose can compromise the structural integrity of the entire system.

If you’ve ever installed a set of brake pads or wheels, you’ll know just how important it is to get the torque right. That’s another clear reason why you should own a torque wrench.

Precision Matters in Modern DIY Projects

These days, many DIY projects—especially those involving vehicles, bicycles, machinery, or even prefabricated furniture—come with exact torque specifications. Whether I’m working on a mountain bike or installing a new sink faucet, those numbers are there for a reason. Manufacturers test and design their products around specific torque values to optimize performance and prevent failure.

Using the correct torque isn’t just about avoiding damage—it often ensures the best performance and longest life for the product. For example, if I’m assembling a carbon fiber bike frame, over-tightening a bolt can cause permanent damage. If I’m repairing suspension parts, under-tightening could result in a part failing under stress.

Modern materials and engineering demand modern tools. That’s why you should own a torque wrench—it’s one of the few tools that can help you meet modern standards in your work.

Where I Use a Torque Wrench in My DIY Life

I’ve found that once I started using a torque wrench, it became a staple across multiple types of projects. Here are a few areas where I regularly put mine to use:

Automotive Repairs

Whether it’s lug nuts, engine components, or suspension bolts, automotive work demands precision. I don’t mess around with guessing when it comes to torque—using the correct settings helps ensure everything stays in place and performs as expected. After torquing lug nuts on my car to factory specs, I’ve had peace of mind on long road trips, knowing my wheels are secure.

Bicycle Maintenance

For road bikes and mountain bikes, especially those with carbon components, using a torque wrench is non-negotiable. These materials are lightweight and strong, but also fragile under excess pressure. A torque wrench helps me adjust seat posts, handlebars, and brake calipers without risking expensive damage.

Home Improvement

I’ve used a torque wrench when bolting down toilets, installing heavy-duty shelving, assembling outdoor equipment, and more. Any time there’s a specific torque requirement—or I need to ensure something won’t wiggle loose over time—it’s the first tool I reach for.

Tool Assembly and Furniture

Even in assembling furniture kits or workshop equipment, many fasteners benefit from even, controlled pressure. Rather than cranking down by feel, I use the torque wrench to avoid overtightening and warping the material.

In short, the number of applications keeps growing, and it constantly reinforces why you should own a torque wrench as part of your core toolkit.

Different Types of Torque Wrenches

Torque wrenches come in several types, each with its own advantages. I’ve used most of them and found that the right one depends on the kind of work you’re doing.

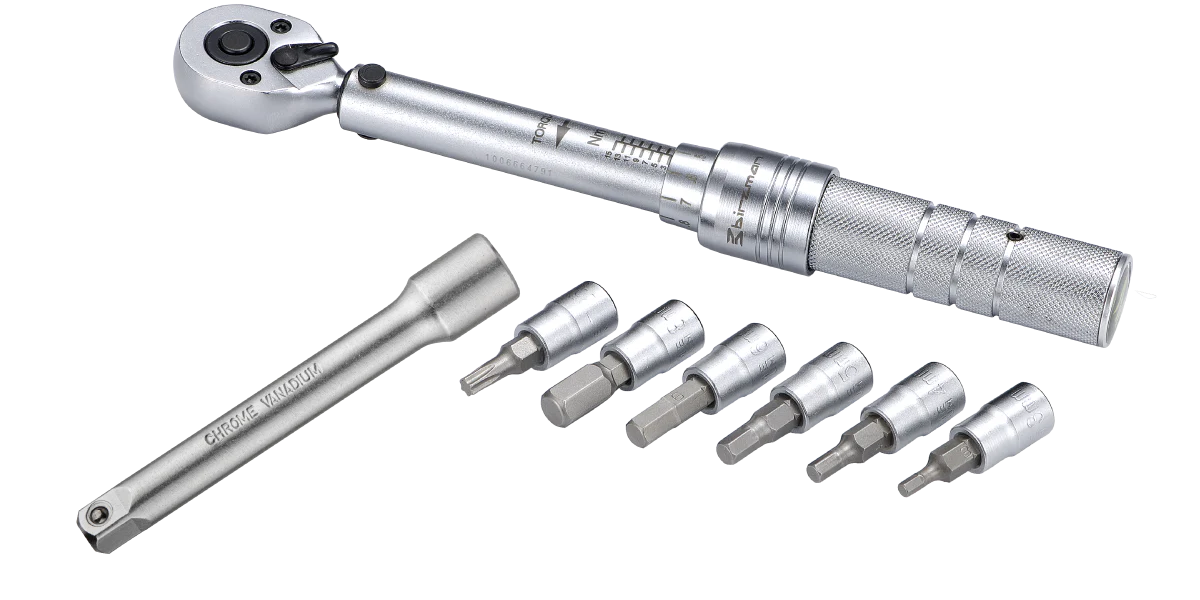

Click-Type Torque Wrenches

This is the most common type, and the one I personally use most often. You set the desired torque value, and the wrench makes an audible “click” when the correct amount of torque is reached. It’s reliable and easy to use, especially for automotive work.

Beam Torque Wrenches

These are simpler, with a needle that points to a scale to show how much torque you’re applying. While not as precise as digital or click wrenches, they’re useful for getting a rough idea and don’t need recalibration as often.

Digital Torque Wrenches

These provide a digital readout and often alert you with a beep or light when you’ve reached the desired torque. They can be more accurate, and I’ve used them for bike maintenance and precision work. The downside is the higher cost.

Dial Torque Wrenches

Less common for general DIY, but extremely precise. They use a dial gauge to show real-time torque application. They’re typically used in labs or settings that require strict quality control.

Whatever your choice, selecting the right type for your tasks reinforces why you should own a torque wrench and understand its place in your tool rotation.

Key Features to Look for

When I bought my first torque wrench, I wasn’t sure what made one better than another. Now, I know exactly what to look for, and it helps to consider these features before buying:

- Torque Range: Choose a wrench that covers the torque values you’ll use most often. For automotive work, a range between 30 and 150 ft-lbs is common.

- Drive Size: Torque wrenches usually come in ¼”, ⅜”, and ½” drive sizes. I use a ½” for cars and a ¼” or ⅜” for bikes and light-duty applications.

- Calibration Certificate: A good torque wrench should be calibrated before use, and ideally come with a certificate showing its accuracy.

- Build Quality: Go for solid metal construction. Plastic components often wear out or affect calibration.

- Ease of Adjustment: It should be easy to set torque values and lock them in, especially if you’re using the tool frequently.

Finding the right model with these features helps ensure you get consistent performance and long-lasting value—and that’s a big reason why you should own a torque wrench in the first place.

Tips for Using a Torque Wrench Correctly

Using a torque wrench isn’t difficult, but there are a few habits I’ve adopted to make sure I’m getting accurate and safe results:

- Always zero it out after use (especially with click-type wrenches) to maintain calibration.

- Tighten bolts in a crisscross or star pattern when working with wheel lugs or flat surfaces to apply even pressure.

- Never use a torque wrench as a breaker bar. It can damage the internal mechanism.

- Store it in its case and avoid dropping it—precision tools require care.

- Check calibration periodically if you use it often or for critical applications.

These practices keep your tool in top shape and ensure your torque values are spot on every time.

Debunking the Myths

Some people think torque wrenches are unnecessary unless you’re doing mechanical or industrial work. That couldn’t be further from the truth. Even basic home repairs benefit from controlled torque. Others say you can “feel” when it’s tight enough—but I’ve seen enough stripped bolts to know that guesswork leads to mistakes.

Another myth is that they’re too expensive. Sure, some high-end digital models cost a lot, but there are excellent click-type wrenches available at reasonable prices. For something that protects your equipment and improves your workmanship, it’s well worth the investment.

That’s yet another reason why you should own a torque wrench—it eliminates the guesswork, prevents damage, and helps you work smarter.

My Favorite Models

If you’re wondering where to start, here are a few models that I’ve used or recommended to others:

- Tekton 24335 ½” Drive Click Torque Wrench – Affordable, reliable, and perfect for automotive tasks.

- Park Tool TW-5.2 ¼” Drive – Ideal for bicycles and small assemblies.

- GearWrench 85077 ½” Digital Torque Wrench – A premium choice with digital accuracy.

- EPAuto ⅜” Drive Click Wrench – Budget-friendly and great for general DIY use.

These models vary in price and application, but each one has helped me get the job done right.

Conclusion

A torque wrench may not be the first tool that comes to mind when assembling your DIY gear, but I can say without hesitation that it’s one of the most essential. From improving safety and performance to preventing costly mistakes, the benefits are too important to ignore. With so many options out there to fit different needs and budgets, there’s really no excuse not to add one to your toolkit.

If you’re serious about your projects—whether it’s car maintenance, bike repairs, or precision builds—then there’s no question why you should own a torque wrench. It’s not just a tool. It’s a standard of doing things right.