10 Power Tool Maintenance Tips to Extend Life

Power tools are a big part of how I get things done in my garage, workshop, and around the house. Whether I’m building furniture, making home repairs, or tackling a weekend project, having dependable tools on hand is essential. But tools only stay dependable if they’re taken care of. Over the years, I’ve learned that routine maintenance is just as important as choosing the right model. That’s why I follow a consistent set of power tool maintenance tips to extend life, cut down on replacement costs, and keep my tools running at peak performance.

Taking care of your gear doesn’t require a lot of technical knowledge or expensive accessories. It mostly comes down to cleaning, inspection, proper storage, and the occasional part replacement. I’ve broken this article into ten clear tips that will help you get the most out of your investment. Whether you’re just starting your DIY journey or you’ve got years of sawdust under your belt, these practices will keep your tools working longer and better.

Keep Tools Clean After Every Use

Dust, debris, and buildup are a power tool’s worst enemy. It might be tempting to finish a job and toss the drill or saw straight back on the shelf, but I’ve learned that a few minutes of cleanup makes all the difference. Wood dust, in particular, has a way of finding its way into vents, motors, and switches.

For most tools, I use a soft brush or a dry rag to wipe down the surfaces. Compressed air is great for getting into tight spaces or cleaning out ventilation grilles. I also make sure to remove any sawdust or grime from the chuck, blade guard, or motor housing. Staying consistent with this step is one of the simplest power tool maintenance tips to extend life that actually works.

Store Tools in a Dry, Protected Area

Moisture is another silent killer when it comes to electric motors and metal components. Even a small amount of humidity can lead to rusted blades, corroded batteries, and malfunctioning switches. I’ve learned to keep all my tools in a climate-controlled area or inside protective cases with moisture-absorbing packs.

If you use a garage like I do, make sure it stays dry and ventilated. I’ve also installed wall-mounted shelves and tool cabinets to keep everything off the floor and away from any leaks or condensation. Proper storage doesn’t just protect your tools—it keeps your workspace safer and more organized, too.

Lubricate Moving Parts

Friction can cause excessive wear on gears, motors, and bearings. That’s why lubrication is a crucial part of tool maintenance. I make it a habit to apply light machine oil or specialized tool lubricants to any moving parts that show signs of wear or stiffness. This includes drill chucks, sliding rails on miter saws, and plunge mechanisms on routers.

If a tool starts making strange noises or feels stiffer than usual, lubrication is usually my first step before taking it apart. Following the manufacturer’s guidance on what to lubricate and how often is key here. It’s a small step, but a powerful one among the power tool maintenance tips to extend life.

Inspect Power Cords and Batteries Regularly

Power cords often take a beating in a DIY workspace. They get pinched, bent, stepped on, and occasionally yanked out of sockets. That’s why I make it a point to inspect all my cords before plugging in. Any frayed insulation, exposed wiring, or loose plugs get addressed right away.

For cordless tools, I check battery terminals for corrosion and clean them if needed using a cotton swab and rubbing alcohol. I also try to rotate my batteries so none of them sit idle too long. A damaged power supply can compromise the tool—and pose a safety hazard.

Replace or Sharpen Blades and Bits

A dull blade doesn’t just make a tool less effective—it forces the motor to work harder and increases the chance of kickback. Whether it’s a circular saw blade, a drill bit, or a jigsaw blade, I check for sharpness and wear regularly. If I notice burning smells, splintered cuts, or slow performance, it’s usually time to sharpen or replace the blade.

Sharpening tools like files, stones, and even specialized jigs make it easier to do this yourself. In some cases, I just keep a few spare blades on hand for quick swaps. Keeping your cutting edges sharp is not only safer but also one of the most effective power tool maintenance tips to extend life.

Check Fasteners and Screws

With all the vibration and torque that power tools generate, it’s no surprise that screws and bolts can work themselves loose over time. I periodically go through my tools and tighten any exposed fasteners, especially around handles, guards, and battery compartments.

Some tools include torque settings or adjustment knobs that need recalibration. I keep a small hex wrench and screwdriver set on my bench specifically for these quick checks. Preventing loose parts now helps avoid bigger mechanical problems down the road.

Don’t Overload or Overheat Tools

Every tool has a limit. Whether it’s torque, voltage, or duty cycle, pushing a tool beyond what it was designed for can wear out the motor and cause breakdowns. If I’m drilling into hardwood or running a saw through thick stock, I make sure to let the tool do the work without forcing it.

If I smell something burning or feel the housing getting hot, I stop immediately and let it cool down. Using the right tool for the job—and not pushing it past its capacity—is one of the more obvious power tool maintenance tips to extend life, but one that many people overlook in the heat of a project.

Use the Right Accessories and Attachments

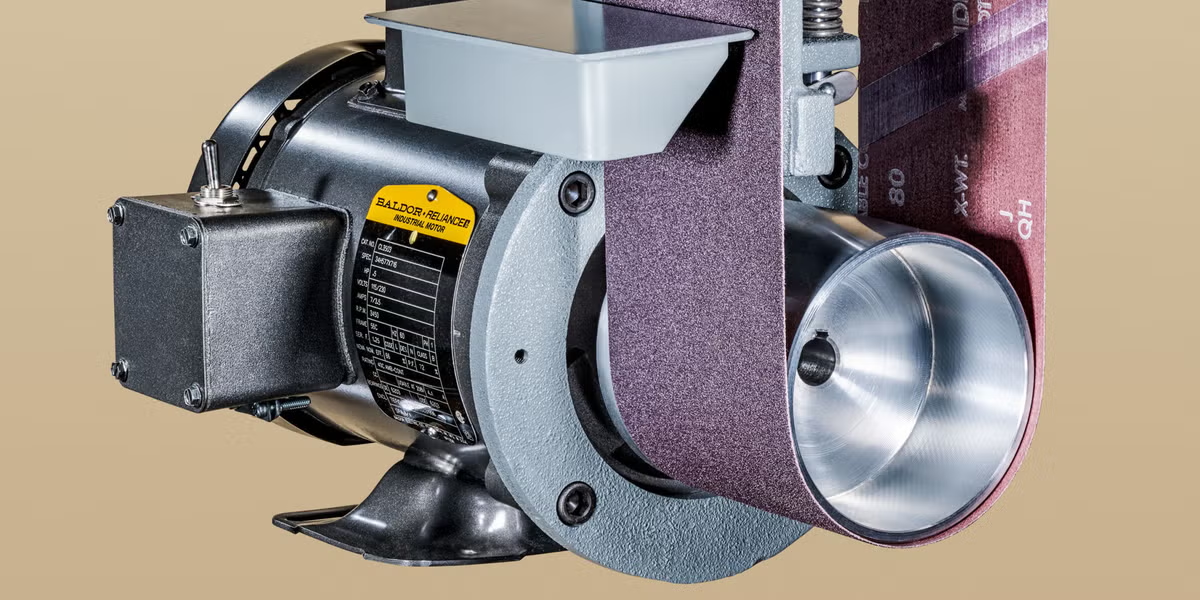

It’s tempting to grab whatever bit or blade is closest and just get to work. But using mismatched accessories can reduce your tool’s effectiveness and even cause permanent damage. I’ve learned to only use blades and attachments that are compatible with the tool’s size, speed rating, and design.

Manufacturers usually offer guidelines for which accessories to use, and I’ve found it worth following them. Using the wrong grinding wheel or an undersized saw blade can wear out the motor, increase vibration, and affect safety. A good fit extends the life of both the tool and the attachment.

Keep Vents and Filters Clear

Power tools generate heat, and they rely on air vents to keep things cool. Blocked vents can cause a motor to overheat quickly, and I’ve seen this ruin otherwise healthy tools. That’s why I regularly inspect and clean air inlets on my tools with compressed air or a small vacuum attachment.

Some tools, like sanders or vacuums, come with internal filters. These need to be cleaned or replaced periodically. A clogged filter restricts airflow and reduces performance. This tip is easy to overlook, but it’s one of the most practical power tool maintenance tips to extend life in tools that generate fine dust.

Follow Manufacturer Maintenance Schedules

Every power tool comes with a manual—though I know most people toss it in a drawer or lose it altogether. I’ve made a habit of keeping digital copies of my manuals so I can look up maintenance intervals, lubrication types, and part numbers when needed.

Many manufacturers include specific instructions for cleaning, inspection, and part replacement. Following these schedules has helped me keep warranty coverage intact and avoid premature tool failure. It also helps me plan ahead, especially for tools I rely on regularly.

Bonus Tip: Label and Organize

While this isn’t directly mechanical, organizing your tools goes hand-in-hand with maintenance. I’ve labeled all my cases and charging docks, and I’ve got shelves sorted by category: cutting, drilling, sanding, etc. This not only keeps everything in its place, but also reminds me which tools I’ve used recently and which ones may need attention.

Regular organization also helps me spot tools that are starting to look worn, or ones that I’ve neglected for a while. It’s a passive way to stay on top of maintenance, and it makes my DIY projects feel less chaotic and more streamlined.

Final Thoughts

Power tools aren’t cheap, and they’re not meant to be disposable. With just a little regular care and attention, you can extend the life of your gear and keep it working like new for years. These ten power tool maintenance tips to extend life have saved me hundreds—maybe thousands—of dollars over time. More importantly, they’ve helped me build a workspace where every tool is ready when I need it.

From keeping blades sharp to storing your tools properly, each habit builds a better relationship with the gear you rely on. Whether you’re repairing a cabinet or building a deck, it’s easier to focus on the work when your tools are clean, safe, and fully operational. The next time you finish a project, take a few extra minutes to maintain your tools—you’ll thank yourself the next time you pick them up.